Key Market Sectors

- 3-D wafer-level packaging

- MEMS

BrewerBOND® 230 Material vs. Wax

| Wax | BrewerBOND® 230 Material | |

|---|---|---|

| Thickness Range | ~ 10 – 35 µm | 20 µm – 150 µm |

| Coating Throughput | Requires multiple coats | Single-coat process |

| Bonding Temperature Range | 95ºC - 110ºC | 100ºC – 130ºC |

| Debonding Temperature Range | 95ºC - 110ºC | 150ºC – 200ºC |

| Thermal Stability Temperature Range | < 120ºC | ≤ 250ºC |

Learn how BrewerBOND® 230 material is replacing wax. [download]

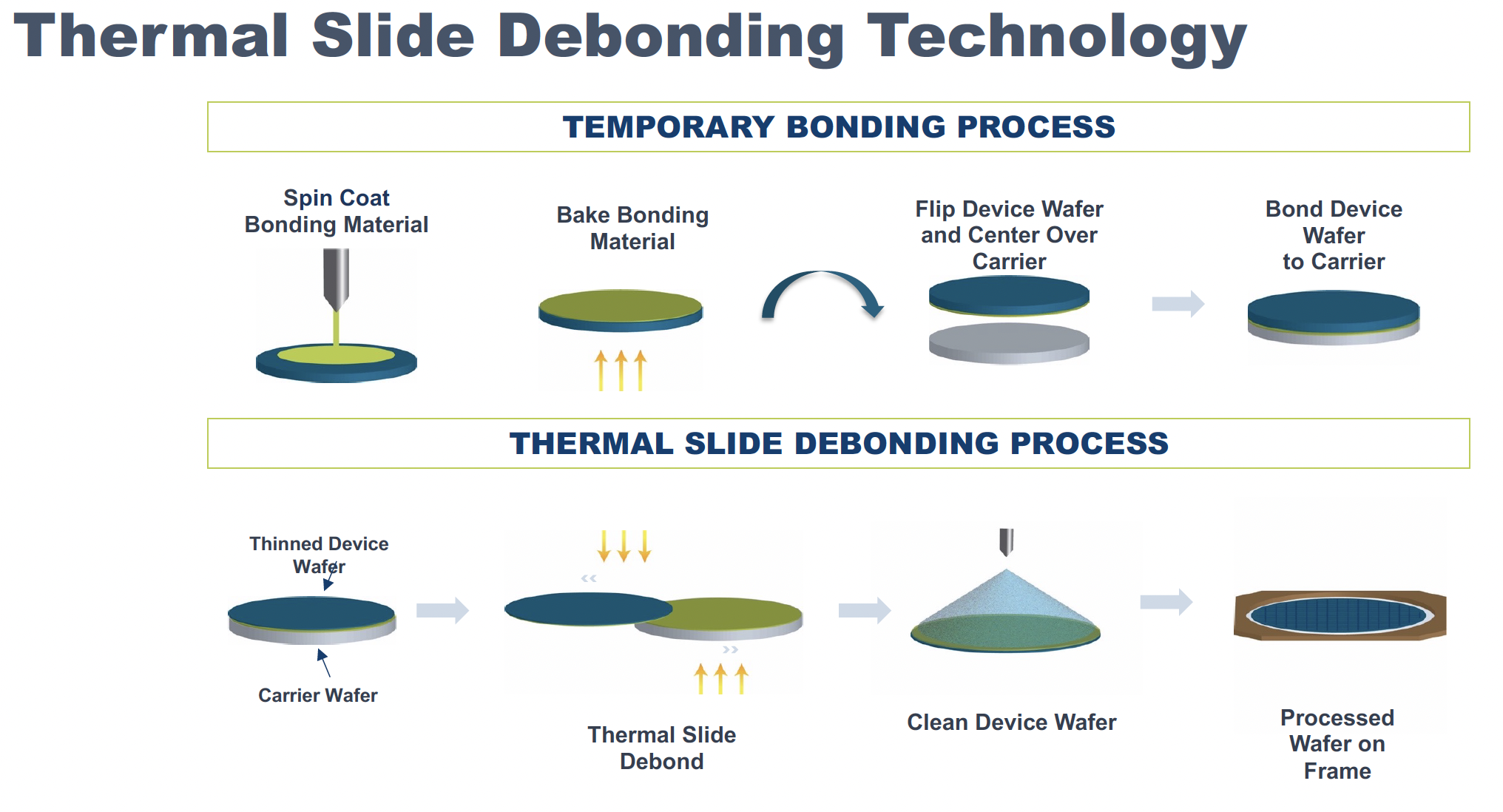

BrewerBOND® 230 material is an organic coating for temporary wafer bonding for MEMS and 3-D wafer-level packaging applications. BrewerBOND® 230 material enables thinning and backside processing through effective bonding and subsequent thermal slide debonding. The material has been developed for use in through-silicon via creation, finishing, and redistribution layer completion in processes up to 220°C.

Benefits

- Low-stress material for high-stress applications

- Broader thickness range in a single coat: up to ~110µm

- Broad temperature range for thermal separation: 150°C to 200°C

- Survives standard back-end-of-line thermal processing

Related Products

BrewerBOND® T1100/C1300 Series Materials enable our unique VersaLayer solution for high-temperature and high-stress applications found within the semiconductor industry.

BrewerBOND® 305 temporary wafer bonding material is an organic coating that enables back-end-of-line (BEOL) processing of ultrathin wafers using standard semiconductor equipment.