WaferBOND® HT-10.11 Material

WaferBOND® HT-10.11 temporary bonding material enables back-end-of-line (BEOL) processing of ultrathin wafers with standard semiconductor equipment.

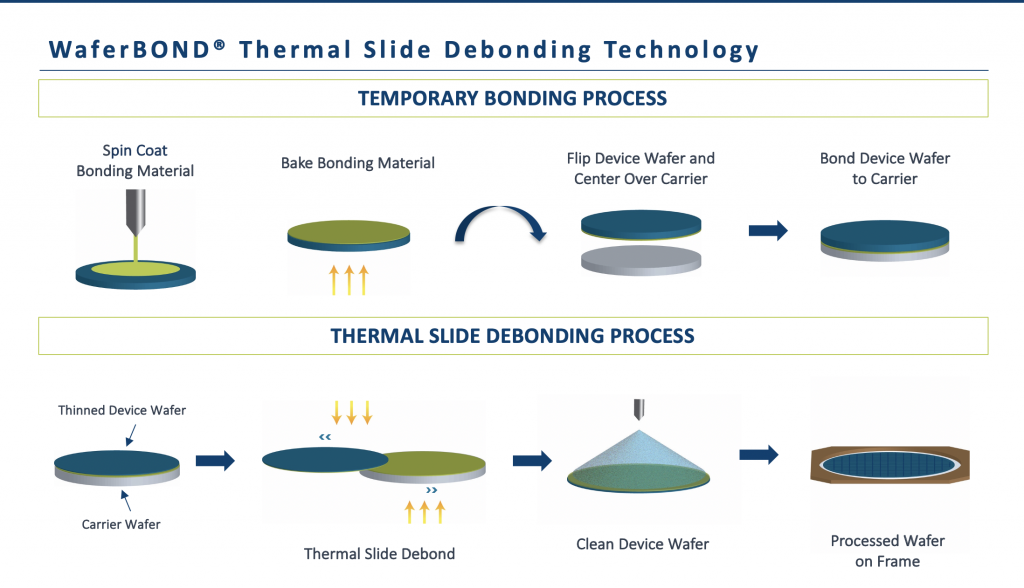

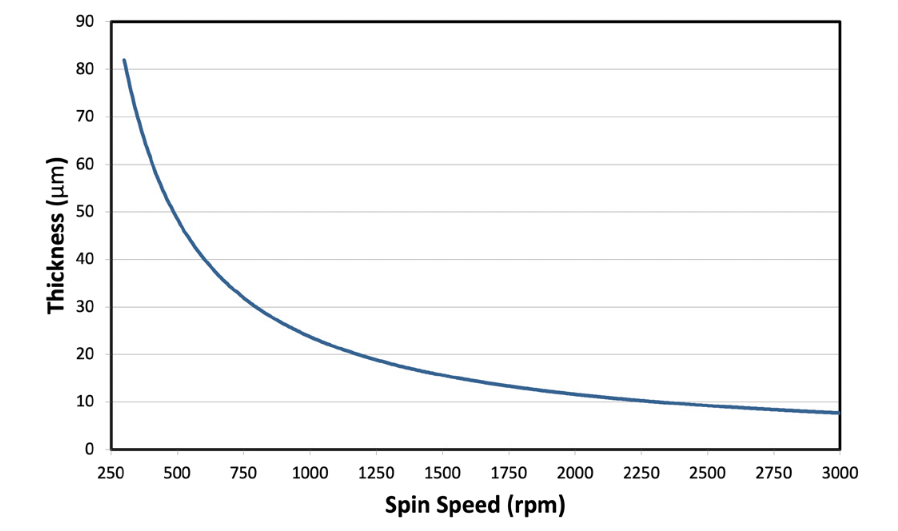

WaferBOND® HT-10.11 material is an organic coating developed for temporary wafer bonding solutions for MEMS and 3-D wafer-level packaging applications. WaferBOND® HT-10.11 material enables effective bonding and support through substrate thinning and backside standard lithographic processing through the utilization of effective bonding and subsequent thermal slide, chemical*, mechanical**, or laser** debonding for thickness < 75 μm. These materials were specifically developed for thin wafer handling (TWH), through-silicon via (TSV) reveal, and redistribution layer (RDL) creation or processes up to 250°C.

*Chemical release debond method requires a perforated carrier wafer or small die size if releasing after dicing

**Mechanical and laser debond methods require a compatible release material