How do manufacturing companies target GHG reduction?

Businesses must reduce their environmental impact. One of the most significant ways to do this is by reducing their carbon footprint, and this starts with monitoring carbon emissions. Carbon emissions are responsible for 81% of overall greenhouse gas (GHG) emissions, and businesses are responsible for a lot of it. The rest of the GHG emissions are methane (10%), nitrous oxide (7%) and fluorinated gases (3%). The EPA created a breakdown of Greenhouse Gas Emissions per economic sector, with transportation, electricity, and industry being the three most prominent contributor sectors directly engaged in the semiconductor industry. Among the many sustainability initiatives Brewer Science leads, the company targets an 80% reduction of scope 1 and 2 emissions from the 2014 baseline by 2030.

Why is greenhouse gas reduction necessary?

The science clearly shows that to avert the worst impacts of climate change and preserve a livable planet, global temperature increase needs to be limited to 1.5°C above pre-industrial levels. According to the United Nations, the Earth is already about 1.1°C warmer than in the late 1800s, and emissions continue to rise. To keep global warming to no more than 1.5°C – as called for in the Paris Agreement – emissions need to be reduced by 45% by 2030 and reach net zero by 2050.

Experts have warned us for decades that inaction will lead to drastic hunger levels, mass migration due to flooding, the collapse of financial markets, and many more socio-economic disasters. That is why leaders and executives are now increasing their attention to sustainability and reviewing their mission and purpose. Sustainability is a business imperative and should not be considered a mere component of corporate social responsibility.

Certifying and reporting carbon emission reduction involves a fairly complex process, mostly governed by the GHG Protocol. The standards vary widely across industries and some companies use a third party to certify their annual CSR report for validation, which leads to differing reporting methods. Therefore, we are partnering with SEMI, and other companies within the industry, to establish straightforward guidelines to ensure consistency of reporting and certifying results across our industry and supply chain. Additionally, companies can disclose their sustainability efforts to the Carbon Disclosure Project, an international non-profit that reports critical environmental data to guide economic decisions for a sustainable business framework.

Businesses must monitor and report their CO2 emissions, which is the critical first step in reducing them. To do so, companies must classify their carbon footprint in three scopes. Scope 1 and 2 are mandatory to report, whereas scope 3 is voluntary and the hardest to monitor. However, companies succeeding in reporting all three scopes could gain a sustainable competitive advantage.

Scope 1: direct emissions

Scope 1 emissions are direct emissions from company-owned and controlled resources. These are emissions released into the atmosphere as a direct result of a set of activities, at an organizational level. Scope 1 emissions are divided into four categories:

Stationary combustion includes all fuels that produce GHG emissions, such as heating and fuel.

Mobile combustion includes all vehicles owned or controlled by the company burning fuel, such as cars, trucks, and vans.

Fugitive emissions are leaks from greenhouse gases, such as refrigeration and air conditioning units. It is important to note that refrigerant gases are a thousand times more dangerous than CO2 emissions. Companies are encouraged to report these emissions.

Process emissions are released during industrial processes, and on-site manufacturing, such as the production of CO2 during cement manufacturing, factory fumes, and chemicals.

One way to target Scope 1 emissions is by taking a closer look at your HVAC design. Brewer Science’s world-class manufacturing facility in Vichy, Missouri features a closed-loop geothermal HVAC design that provides heating and cooling to the building. Geothermal energy does not require burning fossil fuels. Geothermal reservoirs are pools of water deep below the Earth’s surface. The water is used to control the temperature of the geothermal plant or facility. The water used is returned to the ground and can be used again, creating an efficient, sustainable reuse cycle.

Scope 2: indirect emissions – owned

Scope 2 emissions are indirect emissions from the generation of purchased energy, from a utility provider. In other words, all GHG emissions released in the atmosphere, from the consumption of purchased electricity, steam, heating, and cooling.

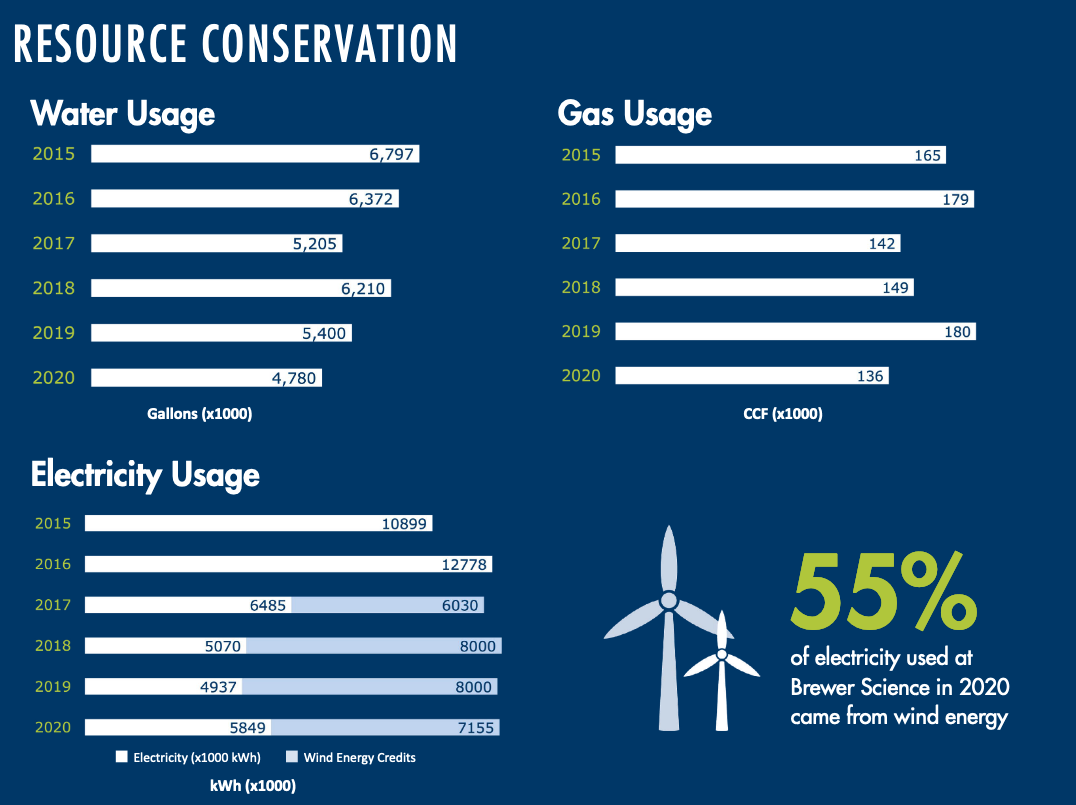

One way to target Scope 2 emissions is by supporting alternative energy sources. In 2019, 62% of electricity used at Brewer Science’s Rolla and Vichy locations were offset by wind energy. We purchase wind energy credits through the electricity company who allocates the resource throughout the town. As more become available, we anticipate a higher percentage of our electricity to be offset by wind energy.

Scope 3: indirect emissions – not owned

Scope 3 emissions are all indirect emissions – not included in scope 2 – that occur in the value chain of the reporting company, including both upstream and downstream emissions. In other words, emissions are linked to the company’s operations. According to GHG protocol, scope 3 emissions are separated into 15 categories. There are two broad categories upstream activities and downstream activities.

Upstream activities fall under several categories: for many companies, business travel is one of the most significant to report, including employee commuting as it results from the emissions emitted through travel to and from work. It can be decreased through public transportation and home office.

Waste generated in operations relates to waste sent to landfills and wastewater treatments. Waste disposal emits methane (CH4) and nitrous oxide (N2O), which cause greater damage than CO2 emissions.

Purchased goods and services includes all the upstream (‘cradle to gate’) emissions from the production of goods and services purchased by the company in the same year. It is useful to differentiate between purchases of production-related products (e.g., materials, components and parts) and non-production-related products (e.g., office furniture, office supplies and IT support).

Downstream activities include customers’ elements of the value chain. It includes emissions from transportation by land, sea, and air, as well as emissions relating to third-party warehousing.

Fuel and energy-related activities include emissions relating to the production of fuels and energy purchased and consumed by the reporting company, in the reporting year that is not included in scope 1 and 2.

Capital goods are final products that have an extended life and are used by the company to manufacture a product, provide a service or, store, sell and deliver merchandise.

Investments are included largely for financial institutions, but other organizations can still integrate it into their reporting. According to GHG accounting, investments fall under 4 categories: equity investments, debt investments, project finance, managed investments, and client services.

Use of sold products is included, concerning “in-use” products that are sold to the consumers. It measures the emissions resulting from product usage, even if it varies considerably. For example, the use of an electronics and sensors will take many years to equal the emissions emitted during production.

At the same time, “end of life treatment” corresponds to products sold to consumers and is reported similarly as “waste generated during operations.” Companies must assess how their products are disposed of, which can be difficult as it usually depends on the consumer. This encourages firms to design recyclable products that limit landfill disposal.

One way to target scope 3 emissions is by organizing community recycling programs. Brewer Science hosts an annual community electronics and household items recycling event that helps divert waste from landfills. In 2021, the event diverted 25.9 tons of residential scrap electronics and 19.51 tons of tires. Brewer Science has recycled over 800 tons since its formal recycling program was initiated in 2002.

Certification programs, such as GreenCircle Certified, help companies stay accountable and give measurable means to their efforts. Brewer Science has achieved GreenCircle Certification Zero Waste to Landfill for seven consecutive years. The Zero Waste to Landfill certification from GreenCircle is one of the most difficult sustainability certifications to meet. GreenCircle will certify an organization for Zero Waste to Landfill Certification if 100% of the waste materials leaving the facility are intended to be diverted from landfill via one of GreenCircle’s acceptable means of diversion. Waste diversion from landfill, defined as the prevention and reduction of generated waste through source reduction, recycling, reuse, or composting, has been characterized as one of the best ways manufacturing companies can demonstrate genuine environmental responsibility.

Being a global leader in the semiconductor industry, Brewer Science made it a mission to address the company’s environmental impact, not only through its products but also its programs. We are targeting an 80% reduction of scope 1 and 2 emissions from 2014 baseline by the year 2030. By understanding the emissions classified in the three scopes of emissions as determined by GHG protocol, companies can take a proactive approach to climate change by adopting more sustainable business practices. Read more about Brewer Science sustainability programs on the Going Green page.