Three Steps to Defect Reduction in Semiconductor Materials

How to Identify Impurities Through Polymer Analysis

Brewer Science conducts polymer analysis and characterization as a fundamental step in quality assurance and control (QA/QC). With over 40 years of experience in the semiconductor market, and surpassing quality expectations of ISO 1900:2015, Brewer Science offers polymer analysis and characterization services, along with other analytical and testing services, to elevate the standards of quality in the industry, thus paving a future of innovation and collaborative development.

Polymer analysis is critical for the QA/QC in material selection, especially in microelectronics where the smallest defect could render a device useless. Brewer Science is working toward a parts per quadrillion purity, which requires a thorough understanding of the materials used in each of our products.

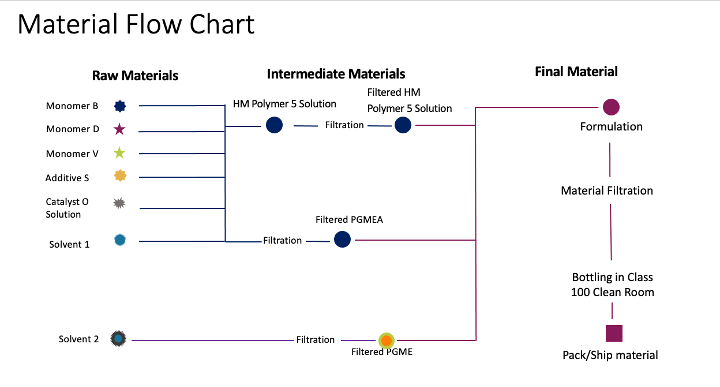

To best understand where impurities originate and their effect on the final product, we break out analytical stages into three main phases: raw materials, intermediate materials, and final materials.

Raw Materials

Each material goes through a process called fingerprinting, which evaluates the raw material’s fundamental characterization and takes a careful look at its basic components. This process is one of the three key steps in our Zero Defects Program. In the example diagram, you can see that the raw materials are characterized into:

- Monomers

- Solvents

- Catalysts

- Additives

Intermediate Materials

As the materials enter the intermediate phase, there is an increased importance in characterization. Characterization of the intermediate is necessary to understand the materials it’s comprised of and determine how it will react in certain applications. Common ways to characterize an intermediate material include

- Molecular weight

- refractive Index

- Dynamic light scattering

- Mass spectrometry

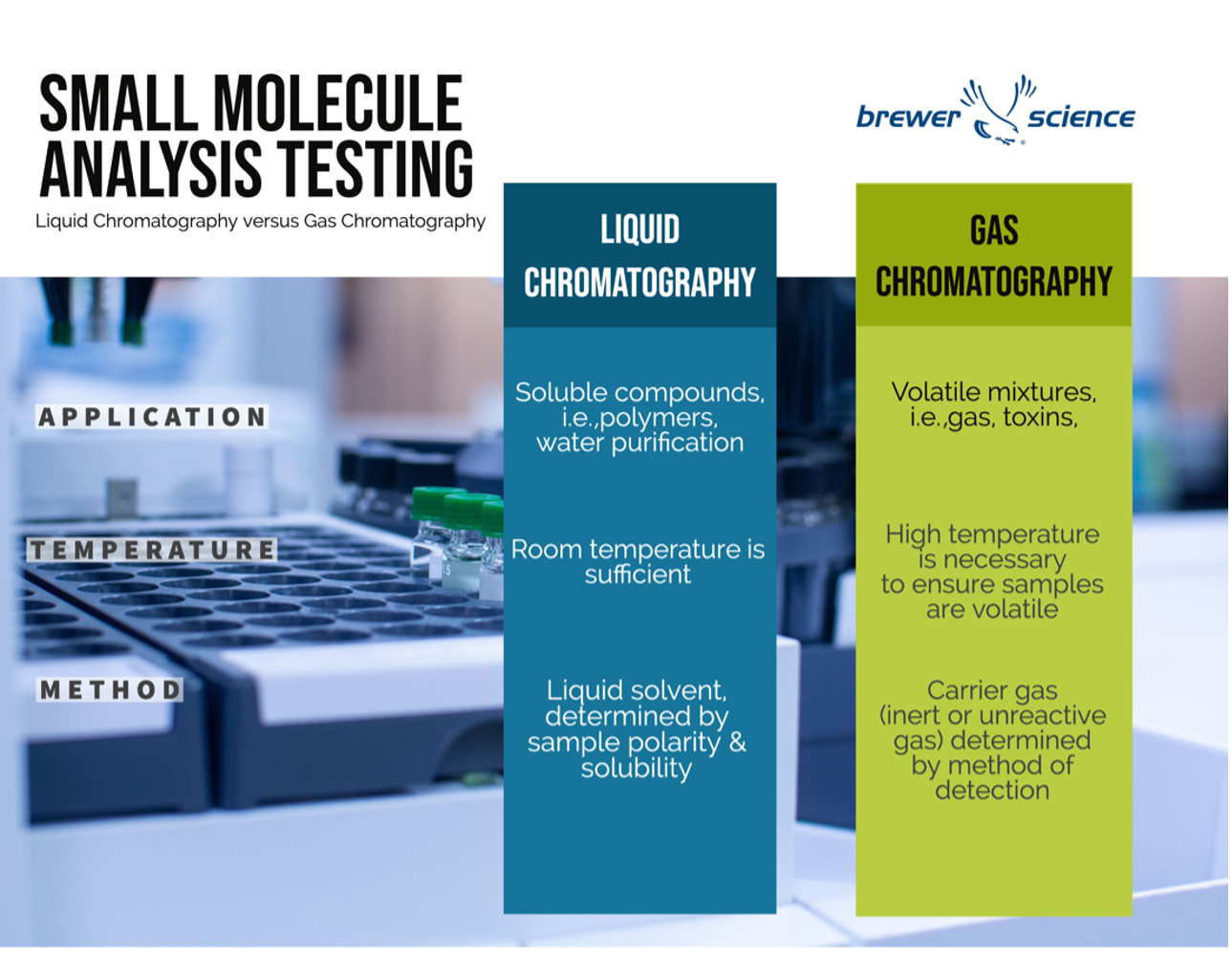

The method of characterization is dependent on the polymer being analyzed. For example, there are several differences between liquid chromatography and gas chromatography testing. Liquid chromatography is used for soluble compounds, whereas gas chromatography is better suited for applications that contain volatile mixtures. The chart summarizes some of the differences just between these two characterization methods.

Final Materials

As the material enters the final phase, testing for purity and eliminating any impurities is the focus, even though this is important throughout the entirety of the process. After analyzing how the material will react in different applications, those measurements are recorded and communicated to the relevant parties.

By having close relationships with our suppliers, we are able to provide contextual information that enables them to improve their products, by eliminating defects on a parts-per-trillion basis.

Because the materials are fingerprinted, characterized, and analyzed, we are able to have a complete and detailed look at the material and thoroughly understand where a defect originated, pinpoint the origin, and eliminate the defect to ensure a successful application.

This video is a basic overview of our manufacturing process, including the wide-range of capabilities within our analytical testing services.

State-of-the-art instruments, combined with our analysts’ knowledge, experience, and skills, enables our advanced material characterization capabilities. We can not only measure the purity of materials, but also report on the impurities with a part-per-trillion ion detection capability. With four decades of serving very diverse technical customers, we understand the importance of taking a specialized approach to each customer’s needs. Please contact us to explore which analytical testing methods are best suited for your application.