It may not look like much, but those little bottles contain one of the most important technological advances of the last 30 years. The 1970s brought an impressive wave of innovation in the United States. In particular, personal computers and electronics began to take root as a mainstay in the home and office.

It may not look like much, but those little bottles contain one of the most important technological advances of the last 30 years. The 1970s brought an impressive wave of innovation in the United States. In particular, personal computers and electronics began to take root as a mainstay in the home and office.

By the end of the ’70s, however, the semiconductor industry had hit a brick wall. As innovation pushed the envelope, current photolithography equipment wasn’t able to keep up. Manufacturers could not make integrated circuit (IC) features smaller than one micron, and no solution seemed evident.

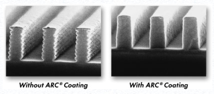

The biggest obstacle (at least in our eyes) was how difficult it was to control light as it bounced off the extremely reflective silicon substrates. The standing wave of light was causing reflective notching in the photoresist and making it very difficult to create more precise and efficient ICs.

The solution Terry Brewer came up with next changed the world.

The Anti-Reflective Coating

The immediate impact of this revolutionary material was two-fold:

1. Greater precision

The anti-reflective coating allowed IC manufacturers to control the light, so to speak, and create and design the coating with greater precision and efficiency. No more unwanted patterns and disruptions appear in the features:

Because we eliminated the reflected light’s negative effect on the photoresist, smaller features could be created and more transistors could be squeezed into the same space and function at a higher level.

2. A blank canvas

Though this wasn’t necessarily a manifest benefit of the ARC® materials, it proved to be an important feature. When added before each layer of photoresist, the coating allows us to planarize the substrate and creates a sturdy, level surface on which to build additional layers. This kind of advance is helping usher in the 3D IC stacking revolution and wafer-level packaging.

A legacy

Though Moore’s Law may be on its way out, there’s no denying that an advance like the anti-reflective coating helped it remain relevant and advance the industry immensely. As demand for smaller IC sizes mounted, it was this coating that helped make it possible. Technology moves quickly, this is true. But the anti-reflective coating has been a mainstay in the semiconductor industry for 30 years. No matter its future, that legacy is worth celebrating.