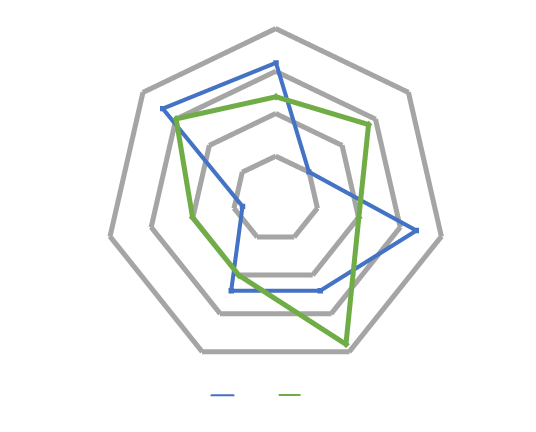

This graphic from ITRS 2015 shows the comparison of DSA and EUV.

Learn more: Brewer Science EUV Products

Brewer Science is dedicated to pursuing the most advanced lithography technologies in the market today. The semiconductor industry relies on geometrical scaling, finding both optical and process solutions to follow Moore’s Law. Directed self-assembly is a leading-edge technique for next-generation lithography, harnessing the thermodynamic properties of block copolymers to create sub-22-nm features without the need for EUV equipment or numerous multi-patterning steps. Brewer Science has partnered with Arkema to develop and commercialize the next generation of DSA materials. Contact us to learn more about our Gen 1 DSA materials, or our next generation high-χ (high-chi) block copolymer solutions.

Advantages of DSA:

- Process simplification over conventional multi-patterning steps

- Same critical dimension distribution

- The pattern is in the material with the pitch defined by molecular weight of the block copolymer

Benefits of DSA Technology:

- Reduced defectivity through material and process optimization

- Increased pattern fidelity

- Increased material quality control at high-volume manufacturing

- Increased throughput at sub-20-nm feature sizes

DSA and EUV: DSA and EUV technologies are on the forefront of advanced lithography processes and complement each other in advancing the industry. EUV improves DSA placement error performance in both contact shrink and contact multiplication by allowing for tighter guiding, while DSA improves EUV pattern fidelity and contact repairing.

Related Products

OptiStack® multilayer systems are our flagship lithography technology, and are used for leading-edge high volume IC manufacturing.

ARC® antireflective coatings are the industry benchmark for reflection control and light absorption during photolithography.