How They Work

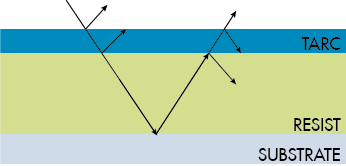

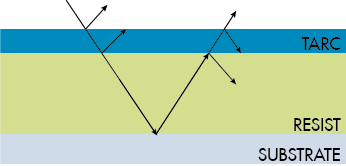

Top Antireflective Coatings

TARCs use the refractive index and thickness of two films (resist and TARC) to control reflectivity through destructive interference only. It does not change the reflectivity of the substrate.

TARCs use the refractive index and thickness of two films (resist and TARC) to control reflectivity through destructive interference only. It does not change the reflectivity of the substrate.

Benefits

Drawbacks:

| Environmental hazard (may contain per- and polyfluoroalkyl substances (PFAS) ) |

| No effect on reflective notching and topography control |

| Intermixing can affect resist |

| Only marginal process improvements as TARC polymers don’t have the optimum n value to completely reduce thin film interference |

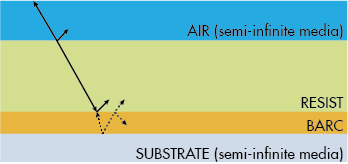

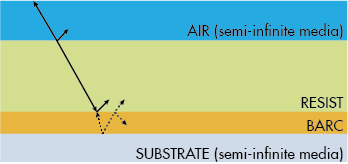

Bottom Antireflective Coatings

BARCs use the refractive index, thickness and absorption of light to control reflectivity. They effectively make the substrate non-reflective.

BARCs use the refractive index, thickness and absorption of light to control reflectivity. They effectively make the substrate non-reflective.

Benefits:

| Better reflection control and process stability |

| Larger process windows |

| Compatible with common resist waste drains |

| Reflective notching and topography control |

| No etch open for wet developable BARCs |

Drawbacks:

| Requires etch open step for dry BARCs |

Both TARCs and BARCs can be used for the same process, with BARCs giving better CD control and wider process windows. BARCs are the preferred choice when you want to get the most out of your expensive lithography equipment.

We have BARCs available across the lithography spectrum: i-line, KrF, ArF, and even assist layers for EUV.

TARCs use the refractive index and thickness of two films (resist and TARC) to control reflectivity through destructive interference only. It does not change the reflectivity of the substrate.

TARCs use the refractive index and thickness of two films (resist and TARC) to control reflectivity through destructive interference only. It does not change the reflectivity of the substrate. BARCs use the refractive index, thickness and absorption of light to control reflectivity. They effectively make the substrate non-reflective.

BARCs use the refractive index, thickness and absorption of light to control reflectivity. They effectively make the substrate non-reflective.